Visual network monitoring with artificial intelligence.

Maintaining the reliable and uninterrupted operation of electricity distribution networks is an extremely difficult task. Overhead networks are exposed to the whims of weather, and service providers also have to deal with deterioration of technology from time to time. This puts strain on human resources involved.

The technology we present helps in the operational process, in risk-based maintenance strategy planning, including visual detection of network element errors and malfunction. This technology makes it possible to reduce the cost of visual inspection of networks to almost one-fifth.

Inspection of objects located in the immediate vicinity of the road network

1 EUR / pole / year

1 EUR/pole/year?

Installing the HAWK System Platform Framework has never been easier. No initial cost, only monthly service fee.

During the conclusion of the contract, the length of the network and the number of columns must be determined

The total number of the objects (column and support structure) is multiplied by 1 euro and divided by 12.

This will be the monthly service fee.

What is included?

HAWK System platform integration into the customer’s environment

GIS with map display, integration, reporting

Full scale SUPPORT – with remote access

Unlimited data collection and AI detection

Object detector

Customer-specific error dictionary for virtual network monitoring*

*Following data collection (via drone, car), the data is uploaded to the HawkGrid system and associated with the network GIS data. At this stage, the system is already capable of allowing the client to perform inspections of electrical network based on the photographs using their own error dictionary in an office environment. Thus, even at this stage, we create the possibility of virtual knowledge transfer, which is the foundation for training neural networks.

What is not included?

The hardware cost of the car’s on-board camera system

The price of the camera system is depending on the number of sensors.

Data collection must be done by the customer

Any car is suitable (also electric), there are no special prerequisites.

Cost of data collection

Ask for our offer. The cost of data collection depends on the method of data collection.

Car Detection Service Cost Calculator

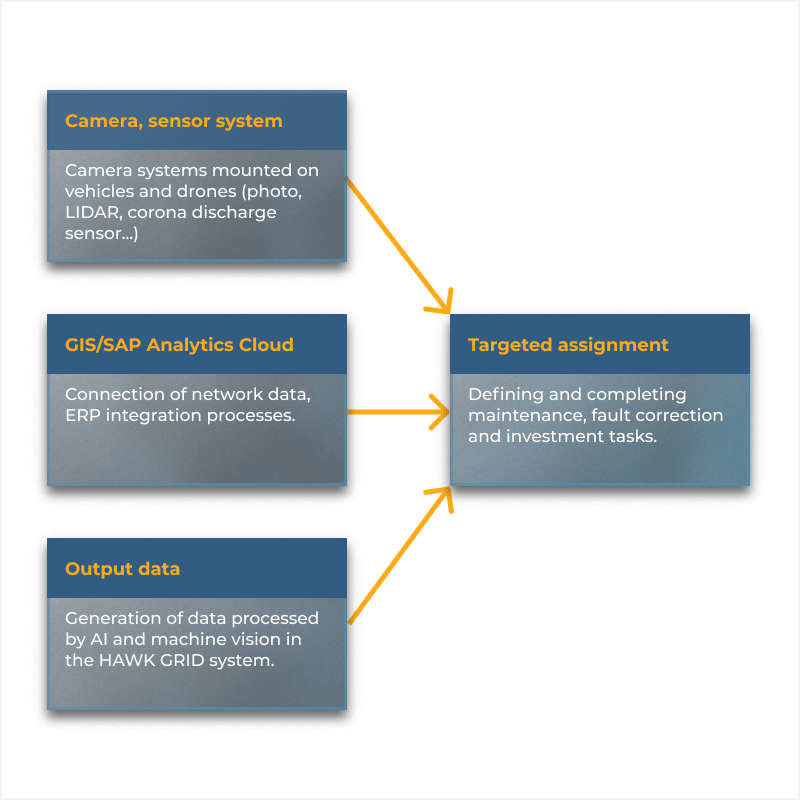

The process

1. Delivering the camera

After you ordered our service, we deliver the camera set to your location via DHL – our strategic delivery partner.

2. The camera set

You get the camera set in a safety suitcase. You can simply install the camera directly on your car.

3. Start recording

You can start recording in your location, the data will automatically be uploaded and integrated into your HawkGrid system.

Our data collection process

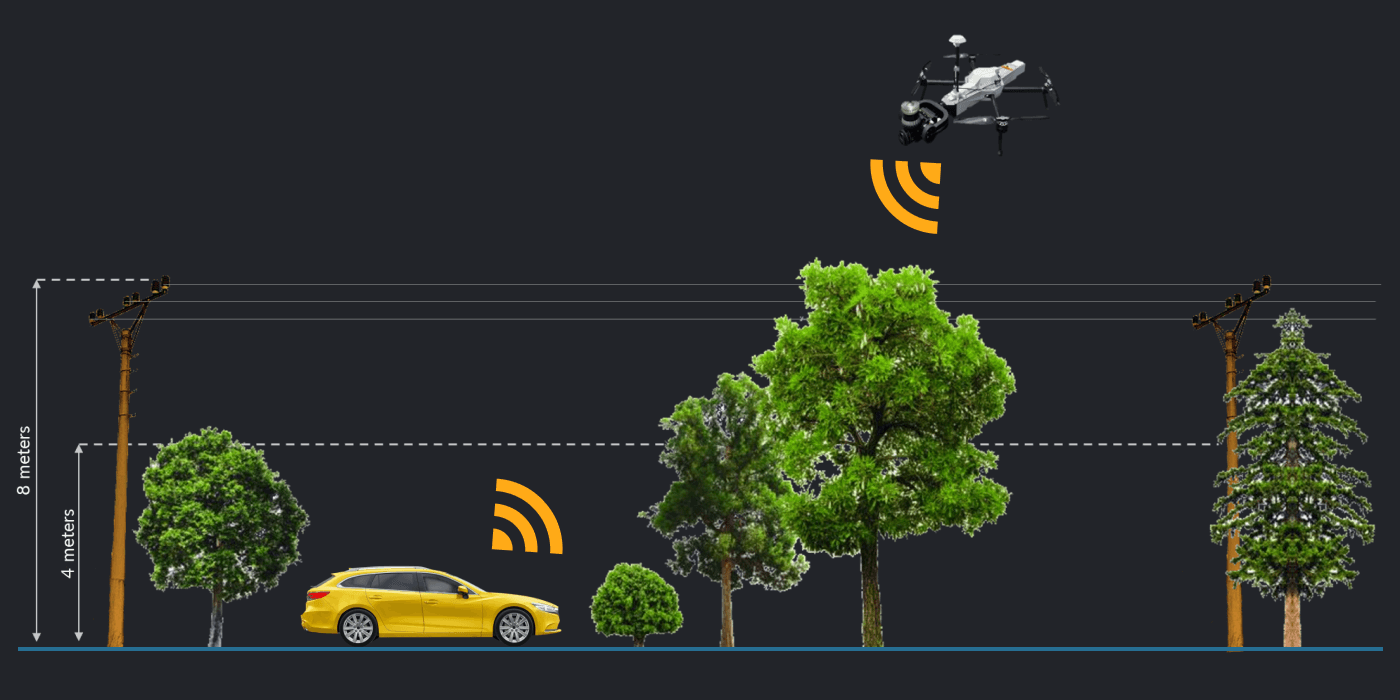

First we collect data on electricity networks. We take pictures with a drone and car-mounted cameras. Lidar, photo, corona discharge detectors, thermal imagers, with gas leak detection systems. With our satellite system we can detect vegetation data. Significant part of the data processing is already done on the on-board system supported by our well trained artificial intelligence.

The cost of data collection can be reduced by up to 50% and the time of data collection by 90%.

Data, photos, and processed results from the network are uploaded to our framework. We visualize the data, assign it to the network, and visualize it according to the customer’s needs.

This visualization can be a simple interface in the customer’s systems or a special user interface tailored to the customer.

Additional data analyzes are performed where the AI independently performs object recognitions and individual detections based on the customer’s needs.

Including but not limited to:

- Electric pole structure. (eg broken, cracked wooden column) vegetation analysis

- Existence of warning labels / indications

- Condition of insulators

- Detection of foreign equipment

Our systems can be fully integrated with the customer’s existing asset management systems. (SAP, ERP, GIS… etc.) The visual inspection of the infrastructures and the information obtained from it are evaluated with the help of AI. The efficient integration with customer systems enables advanced data analysis which can be applied to data-driven decisions for scheduled maintenance tasks and risk-based preventive maintenance.

demo car Camera set

We demonstrate the operation of our car-mounted camera system on distribution networks. During DEMO, we present the object and error recognition algorithm of our artificial intelligence-based system in a real environment. We also show how the collected data is uploaded and how we can integrate the results of the processing into the customer’s business process.

Our customers can choose an area (typically a low-voltage network accessible by car) where they can see and experience real-time object and fault assessment – through the in-car on-board system.

*applies to Europe only.

How can you request a demo?

Contact us at any of our contacts – or send us an enquiry using the details below.

Contact us

fill out the form

Fill out the form and register.

location

CHOOSE A PLACE

Choose an area that is accessible by car.

talk us

Online meeting

Let’s meet and get to know our visual inspection system.

Try it

LIVE DATA COLLECTION

Try our AI supported car mounted system in real time.

data

demo ui DATA check

View the collected data in our cloud-based system.

Vegetation management in urban areas

Ask for our offer and combine it with your error detection process, achieving significant cost savings.

You can find the vegetation analysis of medium and high voltage networks here:

Frequently asked questions

Have a question? Send it to us and we will publish the answer.

More products

Our other solutions that might be interesting for you.